After a heavy rain water is held by berm dam or terrace and therefore farms a pond. This pond slows down and stops the water flow and sedimentation takes place.

| Diameter | 5" | 6" | 8" | 10" | 12" |

|---|---|---|---|---|---|

| A | 780mm | 780 | 850 | 850 | 1015mm |

| 1" holes | 60 | 100 | 168 | 216 | 204 |

| 1" holes | 6 | 10 | 12 | 18 | 12 |

| B | 780mm | 780 | 850 | 850 | 940mm |

| C | 380mm | 380 | 470 | 500 | 610mm |

| D | 195mm | 195 | 225 | 200 | |

| E | 540mm | 540 | 660 | 685 | 1015mm |

Measurements are taken after parts are connected

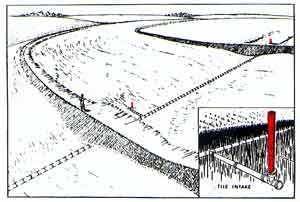

Terraces

The primary purpose of a terrace system is to reduce sheet erosion on cropland fields. Modern terraces where possible can be built parallel to each other to eliminate point rows and to facilitate farming. Terraces have tile inlets connected to an underground tile drainage system. Soil in the runoff settles out in the terrace and all water is removed by the intake within 24 hours. Crops on the terrace receive minimal damage.

-

Calculation of capacity

If the depth of the water in the collection area is greater than approximately 16 inches, the inlet will be full and will fill a tile its own size or larger. Deeper water (more head pressure) could actually fill a tile of a greater diameter. Thus several factors are important in determining the size of the inlet needed.- The expected amount of runoff must be calculated and adequate storage provided.

- Inlet size and tile capacity must be adequate to remove pounding within the desired time period after a heavy rainfall.

- Rate of removal must be low enough to ensure pounding and thereby facilitating sedimentation.

- Trash can in some situations decrease the rate of water removal. (see flow rate chart)

- The top of the riser ( small holed orange section) should be at ground level. This can be achieved by adjusting the tile in various ways.

- A complete riser section can be used for deep tile; approximately 43” depth

- by cutting sections in half (on both lines indicated) each half can be used for installations approximately 27” deep.

- On 5 and 6 inch inlets, various steps in between can be attained by either snapping the two halves together, resulting in 4” drop from maximum height or cutting 4” off smaller end of either piece (just above the raised rib) and then using the next rib for the snap fit.

- In sandy conditions, where holes in the riser section are not desired, a tile sock can be used to cover them. In these cases a black section can also be used as a non perforated riser although adjustability will be reduced.

- The tee is constructed with one closed end that can be cut off with a hand saw if the inlet is used “inline” on a field tile instead of “offset”. Both the five inch and six inch tee have built in couplers for 6 inch tile. A reducer coupler is available to adapt to 4” or 5” tile.

- All sections should be firmly pushed together to snap the bead into the corresponding groove in the bell of the receiving fitting.

- A bar guard is available for the top of the inlet if an open top is required.